Researchers from MIT have developed an AI tool for determining the stress a material is under through analysing images.

The pesky laws of physics have been used by engineers for centuries to work out – using complex equations – the stresses the materials they’re working with are being put under. It’s a time-consuming but vital task to prevent structural failures which could be costly at best or cause loss of life at worst.

“Many generations of mathematicians and engineers have written down these equations and then figured out how to solve them on computers,” says Markus Buehler, the McAfee Professor of Engineering, director of the Laboratory for Atomistic and Molecular Mechanics, and one of the paper’s co-authors.

“But it’s still a tough problem. It’s very expensive — it can take days, weeks, or even months to run some simulations. So, we thought: Let’s teach an AI to do this problem for you.”

By employing computer vision, the AI tool developed by MIT’s researchers can generate estimates of material stresses in real-time.

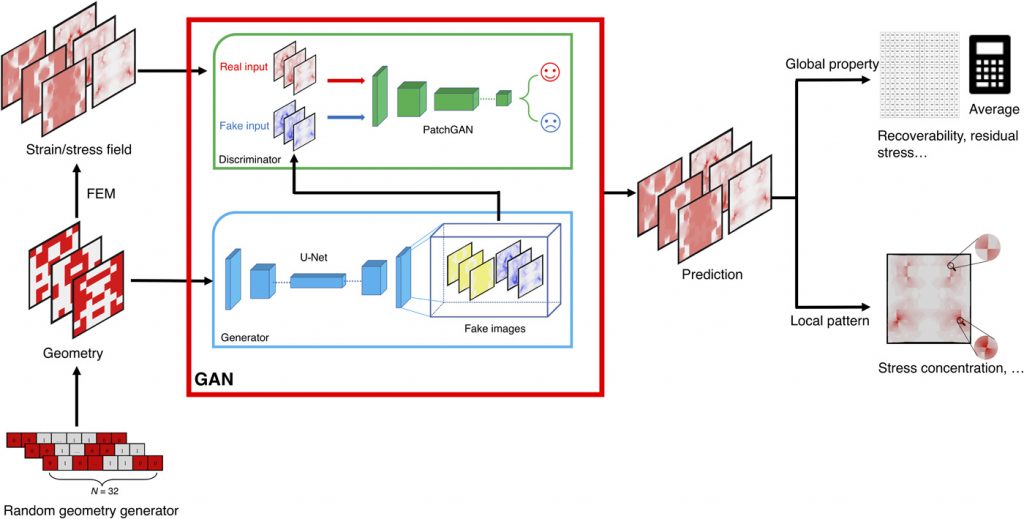

A Generative Adversarial Network (GAN) was used for the breakthrough. The network was trained using thousands of paired images—one showing the material’s internal microstructure when subjected to mechanical forces, and the other labelled with colour-coded stress and strain values.

Using game theory, the GAN is able to determine the relationships between the material’s appearance and the stresses it’s being put under.

“From a picture, the computer is able to predict all those forces: the deformations, the stresses, and so forth,” Buehler adds.

Even more impressively, the AI can recreate issues like cracks developing in a material that can have a major impact on how it reacts to forces.

Once trained, the neural network can run on consumer-grade computer processors. This makes the AI accessible in the field and enables inspections to be carried out with just a photo.

You can find a full copy of the paper here.

(Photo by CHUTTERSNAP on Unsplash)

Interested in hearing industry leaders discuss subjects like this? Attend the co-located 5G Expo, IoT Tech Expo, Blockchain Expo, AI & Big Data Expo, and Cyber Security & Cloud Expo World Series with upcoming events in Silicon Valley, London, and Amsterdam.